2025-09-30

2025-06-24

2025-06-13

2024-08-05

2024-06-25

2024-03-12

Address: 3F , Blg 7 West, Sinosteel Building,Maque Industry Village Nanshan,Shenzhen,518057,Guangdong

Phone: +86-755-26971006

Mobile: 13751075276

Email: sales@acroview.com

Facing the "difficult start" in 2020, China's manufacturing industry has been severely hit, and the difficulty of resuming work and production has become prominent. The results show that applications such as production automation and remote operation and maintenance have greatly enhanced the survival strength of enterprises. The more intelligent the enterprise, the stronger the anti-risk ability. After this epidemic, the traditional electronics manufacturing industry will more actively think about and pay attention to the intelligent construction of factories, and promote the application of automated production lines.

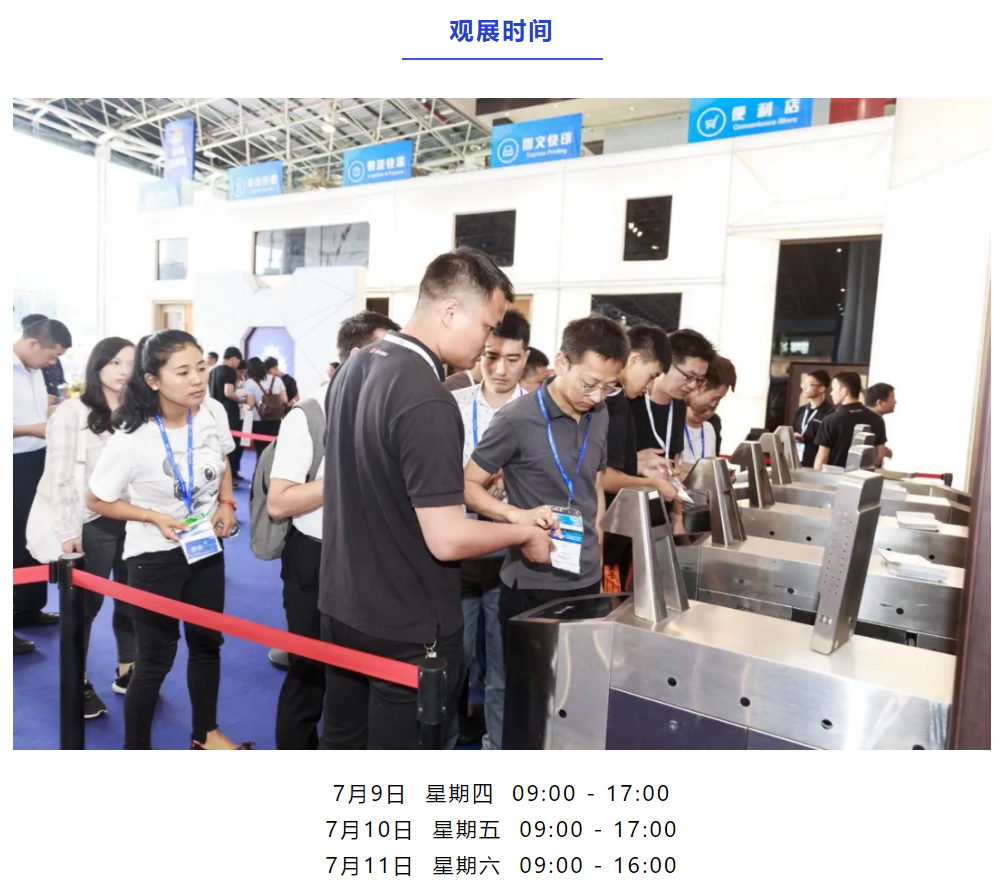

From "delay" to "restart", the 4th China Electronics Manufacturing Automation & Resources Exhibition (CMM Exhibition for short) will be held at Dongguan·Guangdong Modern International Exhibition Center on July 9-11.

Cover the whole process of electronics manufacturing and accelerate the intelligentization of electronics manufacturers

As a grand event for the electronics manufacturing industry, the CMM exhibition brings together outstanding electronics manufacturing equipment manufacturers in the industry. The exhibits cover the entire electronics manufacturing process, including SMT, DIP, smart warehousing, test terminals, packaging sections, assembly sections, manufacturing environment, peripheral equipment, information and management System, process materials and tools, etc., provide the latest solutions for the digitalization, intelligence, automation, unmanned, and optimal allocation of resources for electronic manufacturing factories, and accelerate the development of intelligent manufacturing in China's electronic manufacturing factories.

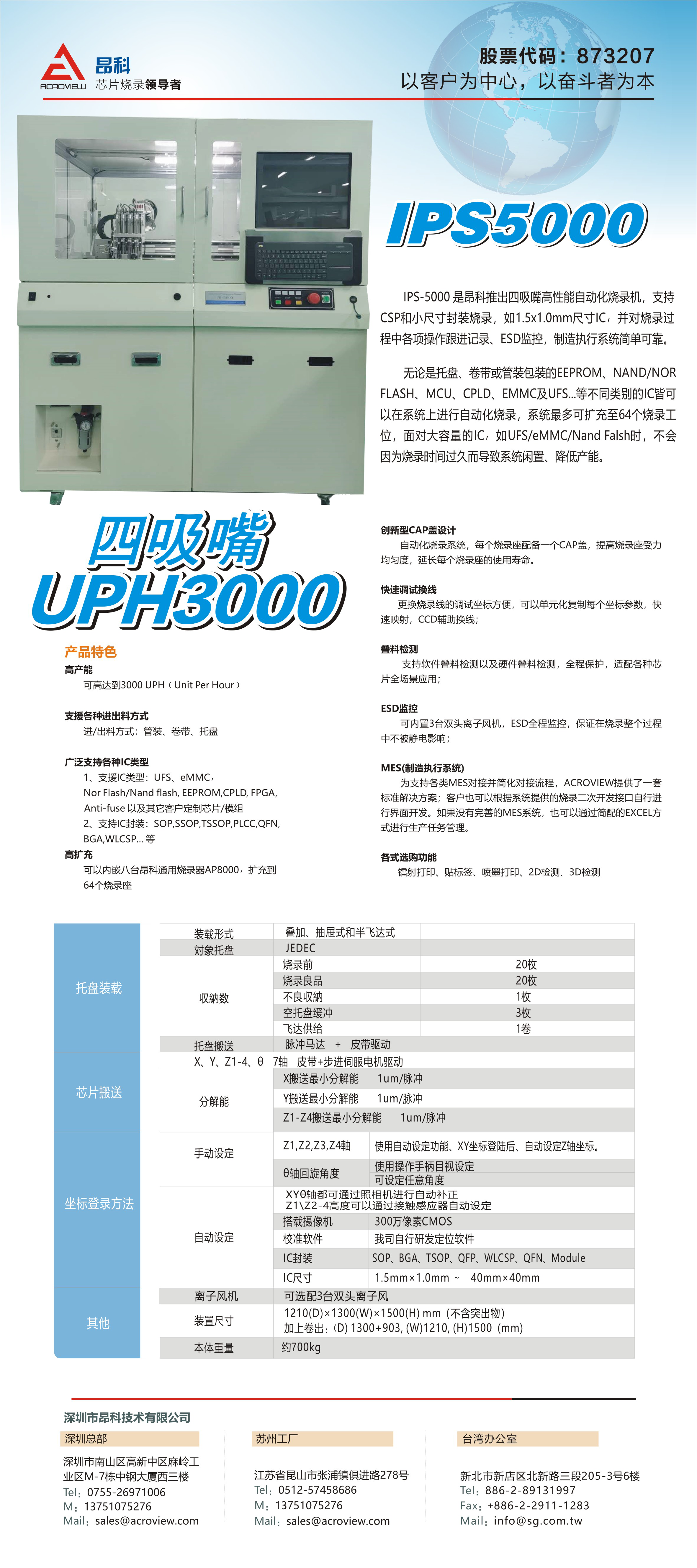

OncoTech (stock code: 873207) was established in February 2013. As a leader in the chip programming industry, this time we will participate in the exhibition together with our agent Shenzhen Fu Ruichen Electronic Technology Co., Ltd., showing the latest automation architecture IPS5000 And UFS mass production burner and UFS engineering burner;

The IPS-5000 automatic burning machine is the latest product of Onco. It supports CSP and small package burning, such as 1.5x1.0mm IC. It also records various operations during the burning process and monitors ESD to make burning changes. To be simpler and more reliable.

Different types of ICs such as EEPROM, NAND/NOR FLASH, MCU, CPLD, EMMC, UFS... etc. can be automatically burned on the system, whether it is pallet, tape or tube packaging, and the system can be expanded to 64 The burning station, when facing large-capacity ICs, such as UFS/eMMC/Nand Falsh, will not cause the system to be idle and reduce production capacity due to the long burning time.

UFS-A4 is a UFS mass-produced burner/UFS-A1 is a UFS engineering-developed burner

Support UFS specification version: V2.0, V2.1 and V3.0;

Support UFS high speed Gear 1 Rate A ~ HS-Gear 3 Rate B.

Support UFS Descriptors, Attributes, Flags configuration;

Support UFS Logical Units read, write and format operation.

Support UFS RPMB function.

Support UFS Wipe operation.

Support UFS device part number and capacity identification.

Comply with UFS 3.2 Gen 1 specification.

The mass-produced adapter supports 4 UFS devices for asynchronous programming.

The powerful universal UFS Image Builder software configures the partition.

Provide real-time statistical information display and session log report.

Burning performance up to Read: 428MB/s and Write: 254MB/s

The following is a guide to the exhibition, please collect it

Dear, scan to add WeChat as a friend

Online Service

Phone

Top