2025-12-26

2025-09-30

2025-06-24

2025-06-13

2024-08-05

2024-06-25

Address: 3F , Blg 7 West, Sinosteel Building,Maque Industry Village Nanshan,Shenzhen,518057,Guangdong

Phone: +86-755-26971006

Mobile: 13751075276

Email: sales@acroview.com

[Guide] On-line programming, the chip is first attached to the PCB, and then programmed. Due to the flexibility of online programming (after the product is first produced, different firmware can be temporarily burned according to the user's order) and easy rework (reburning directly on the board), more and more factories choose online programming Plan. Since each target board is burned online, the chip is first attached to the PCB and then burned.

In response to the needs of online programming, Acroview Technology has developed various online programming solutions for customers. Acroview Universal Writer AP8000 (PT100), in the automotive electronics industry, because of the relatively large homogeneity of hardware and software differences There are many requirements for chemistry, so there is a lot of demand for online programming;

Figure 1: Online one-to-one burning

Figure 2: Online one-to-eight burning

Due to the flexibility of online programming (after the product is first produced, different firmware can be temporarily burned according to user orders) and easy rework (reburning directly on the board), more and more automotive electronics companies choose online Burning scheme.

Figure 3: Online burning picture of customer simple fixture

Acroviewtech's universal online programmer AP8000 supports secondary development with Labview, C#, VC, etc., and has developed a variety of automated online programming solutions for customers

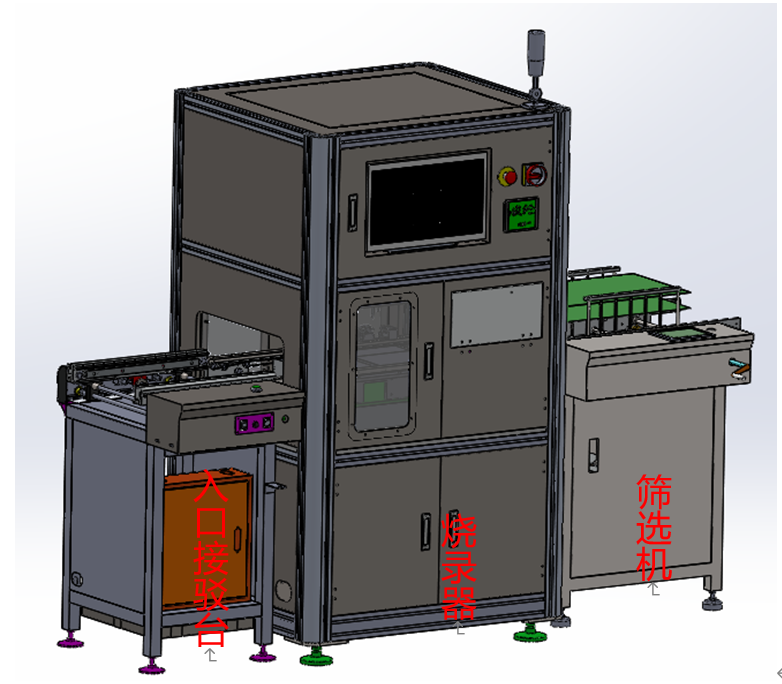

Figure 4: EICT-3000 automatic on-board burning

Figure 4: Automatic on-board programming solution

It not only realizes online burning, but also connects to the MES system. Acroviewtech's online burning solution connects to the customer’s MES system, so that burning is no longer an information island, which can help production managers reduce management costs and improve management efficiency. The intensity of control can achieve the goal of refined management and enhance the core competitiveness of the enterprise.

Acroviewtech (stock code: 873207) is the first domestic listed company in the burner (programmer) industry, independently owns the R&D, production and service of burner (programmer), automatic burner and automatic online burner At the same time, it has established R&D and production service bases in Shenzhen, Taipei, Suzhou, Yangzhou, and Shanghai. It is the preferred brand of programming solutions for large factories at home and abroad. Acroviewtech has more than 10 years of rich experience in the development, manufacturing and service of programming equipment Experience, world-leading technology, and is committed to providing customers with innovative programming solutions and products. We are working hard to make outstanding contributions to the reliability, security and intellectual property protection of programming equipment. Acroview has always firmly believed that the pursuit of quality and technology will make more and more electronics manufacturers choose Acroview as their trusted partner. New products are continuously being released, please stay tuned.

Dear, scan to add WeChat as a friend

Online Service

Phone

Top